-

Height-Adjustable Working Tables

-

Engine Powered

-

Construction Screws

-

Special Materials CRISCO

-

Accessories - Tool Materials

-

Blades

- Aluminium Cutting Blades

- Aluminium Cutting Blades (Special Tooth for Thin Profiles)

- Aluminium Cutting Blades (Special Tooth)

- Diamond Blades for General Cut

- Diamond Premium Blades

- Mild Steel Cutting Blades

- Multi-Material Cutting Blades

- Multi-Material Diamond Blades

- Saw Blades VIRUTEX

- Scorring Saw Blades

- Solid Surfaces Cutting Blades (Special Alloy & Tooth)

- Stainless Steel Cutting Blades

- Thin Steel Cutting Blades

- Wood Blades Fine Cut

- Wood Blades General Cut

- Wood Composite Cutting Blades (Hollow Tooth)

- Wood Composite Cutting Blades (Particleboard, MDF, OSB etc.)

- Wood Composite Cutting Blades for Machines (Special Tooth)

- Wood Cutting Blades (Solid Wood)

-

Blades

-

Glue Feeders

-

Wood Repair System

-

Pneumatic Tools

-

Power Tools

-

Battery Tools

-

Hand Tools

-

Fastening Materials

-

Upholstery Machines

-

Digital Measuring Tools

-

Clamping Systems

-

Sanding Systems

- Manufacturer: FASCO

- SKU: 27.0149

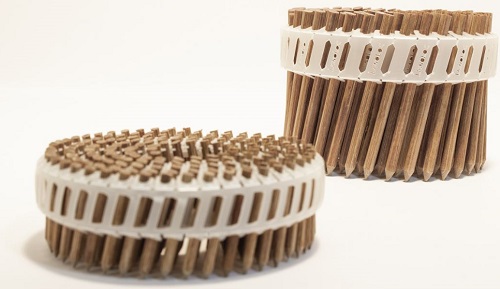

LignoLoc is the first ever fireable wooden nail for future- oriented use in industrial production and ecological timber construction (among many other applications).

The Lignoloc System consists of the LiGNOLOC pneumatic nailer from FASCO F44AC CN15-PS60A and the wooden nails in the dimensions of 40mm, 50mm, 60mm & 65mm.

Request a Quote for: Lignoloc Pneumatic Nailer F44AC CN15-PS60A

FASCO-BECK comes with the further development of this innovative product!

The System consists of the F44AC CN15W-PS60A pneumatic nailer and beech wood nails with a length of 40 to 60mm in diameters of 4.7 & 5.3mm.

The most important asset of this system is that there are no traces of corrosion in the wood!

The revolutionary LIGNOLOC Nails are made from indigenous beech wood, and boast a tensile strength similar to aluminium nails.

Their mechanical properties allow the nails to be driven into solid structural timber with the FASCO LignoLoc pneumatic nailer, without any pre-drilling, to form an inseparable bond with the timber.

The special design of the LignoLoc nail tip and the large amount of heat generated by friction when the nail is driven in cause the lignin of the wooden nail to weld with the surrounding wood to form a substance -to- substance bond.

The phenomenon of lignin welding was established in 1998 and has since been verified by the BECK Fastener Group in collaboration with scientists at Hamburg University by means of UV-scanning of the cell structure.

LignoLoc is the first ever fireable wooden nail for future- oriented use in industrial production and ecological timber construction (among many other applications).

KEY BENEFITS

Quick and simple processing with FASCO pneumatic nailers.

Hardly any water absorption, so no expansion.

High holding power thanks to lignin welding.

Resistant to fungal infestation.

No streaking or bleeding on the wood.

More environmentally friendly than metal fasteners.

Installed significantly than wood dowels.

No pre-drilling.

No wood glue necessary.

Made of indigenous beech wood.

Better fire protection in wood structure than steel or metal fasteners.

No thermal bridges, so better insulation values.

Tensile strength similar to aluminium nails.

Less tool wear when cutting nailed wooden components subsequently.

USE IN ENVIRONMETALLY FRIENDLY WOOD PROCESSING

Metal free and made of Wood.

The LignoLoc System from BECK opens up countless applications options for you - whether it be indoors or in areas susceptible to corrosion:

-Interior timber cladding

-Timber facades

-Wooden fences

-Wooden furniture

-Sauna building

-Floors: OSB - und real wood flooring

-Working with reclaimed wood

-Boat building

-Wooden coffins and many more

-LignoLoc wooden nails can be used in various ways in the production of multilayer solid wooden boards. Depending on the manufacturing process, they are used for fixing the layers temporarily or as a replacement for aluminium nails and wooden dowels, or else they give rise to completely new processing methods. This means time-related advantages and ecological benefits for the industry.

Exemplary Ecology

From production to recycling, Lignoloc wood nails have outstanding eco-friendly properties. European beech is a renewable raw material with short transport rootes.

According to a study by the Nova Institute, the production of a Lignoloc wood nail causes only a quarter of the greenhouse gasses compared to a technically comparable steel nail.

Video

Specification

Tool's Specifications

Fastener's Specifications

FASCO-BECK comes with the further development of this innovative product!

The coil nailer is specially designed for LIGNOLOC® wooden nails, with a tool-free depth of drive adjustment. Works nails with diameter up to 5.3 mm and length up to 90 mm - High power, no predrilling necessary in wood with density up to 420 kg/m³.

The most important asset of this system is that there are no traces of corrosion in the wood!