-

Height-Adjustable Working Tables

-

Engine Powered

-

Construction Screws

-

Special Materials CRISCO

-

Accessories - Tool Materials

-

Blades

- Aluminium Cutting Blades

- Aluminium Cutting Blades (Special Tooth for Thin Profiles)

- Aluminium Cutting Blades (Special Tooth)

- Diamond Blades for General Cut

- Diamond Premium Blades

- Mild Steel Cutting Blades

- Multi-Material Cutting Blades

- Multi-Material Diamond Blades

- Saw Blades VIRUTEX

- Scorring Saw Blades

- Solid Surfaces Cutting Blades (Special Alloy & Tooth)

- Stainless Steel Cutting Blades

- Thin Steel Cutting Blades

- Wood Blades Fine Cut

- Wood Blades General Cut

- Wood Composite Cutting Blades (Hollow Tooth)

- Wood Composite Cutting Blades (Particleboard, MDF, OSB etc.)

- Wood Composite Cutting Blades for Machines (Special Tooth)

- Wood Cutting Blades (Solid Wood)

-

Blades

-

Glue Feeders

-

Wood Repair System

-

Pneumatic Tools

-

Power Tools

-

Battery Tools

-

Hand Tools

-

Fastening Materials

-

Upholstery Machines

-

Digital Measuring Tools

-

Clamping Systems

-

Sanding Systems

Request a Quote for: Glue-Spreading Machine for Windows and Doors 9037

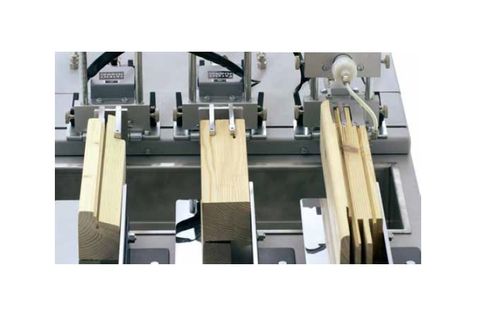

Glue-spreading machines for windows and doors

Description: gluing machines for window and door components.

General features: easy to use, powered pneumatically, no electrical connections needed.Consisting of a base, a platform with carriage and a tank in the base to hold the glue.

Available with 2/3/4 heads, with a wide range of standard and customised nozzles depending on the profile to be glued. Can be matched with a vast range of accessories. Designed specifically for the window and door industry, for gluing tenons and joints from 3 to 10 cm deep. The glue is dispensed through the nozzle on the gun, while the carriage reverses so that the glue is spread perfectly over the whole tenon.

Standard adjustments:

- flow/quantity of glue onto the gun

- flow of glue dispensed onto the nozzle according to the height

of the tenon

- flow of glue dispensed according to the depth of the tenon

- carriage speed (faster carriage, less glue / slower carriage, more glue)

Nozzles: always custom made to measure.

Glue - properties: use only PVA glues with a viscosity between 8.000 and 15.000 mPa s, working temperature 20°/68°F.

Fields of application: window and door components.

Advantages: reduced working time compared to manual and traditional gluing systems, considerable savings in glue with reduced wastage, precise spreading and stronger join between the parts.