-

Height-Adjustable Working Tables

-

Engine Powered

-

Construction Screws

-

Special Materials CRISCO

-

Accessories - Tool Materials

-

Blades

- Aluminium Cutting Blades

- Aluminium Cutting Blades (Special Tooth for Thin Profiles)

- Aluminium Cutting Blades (Special Tooth)

- Diamond Blades for General Cut

- Diamond Premium Blades

- Mild Steel Cutting Blades

- Multi-Material Cutting Blades

- Multi-Material Diamond Blades

- Saw Blades VIRUTEX

- Scorring Saw Blades

- Solid Surfaces Cutting Blades (Special Alloy & Tooth)

- Stainless Steel Cutting Blades

- Thin Steel Cutting Blades

- Wood Blades Fine Cut

- Wood Blades General Cut

- Wood Composite Cutting Blades (Hollow Tooth)

- Wood Composite Cutting Blades (Particleboard, MDF, OSB etc.)

- Wood Composite Cutting Blades for Machines (Special Tooth)

- Wood Cutting Blades (Solid Wood)

-

Blades

-

Glue Feeders

-

Wood Repair System

-

Pneumatic Tools

-

Power Tools

-

Battery Tools

-

Hand Tools

-

Fastening Materials

-

Upholstery Machines

-

Digital Measuring Tools

-

Clamping Systems

-

Sanding Systems

- Manufacturer: MAFELL

- SKU:

• Minimal space requirement - the workpiece always remains in the same position.

• Considerable time-saving - due to quick and easy adjustment of length, angle and tenon dimensions.

• Chip waste is extractable as a matter of course.

• Maximum timber dimensions 500 x 250 mm, at 0° and 200 x 250 mm at 60°.

Request a Quote for: Tenoner ZAF 250 Vario

• Tilt range of cutting unit up to 60°.

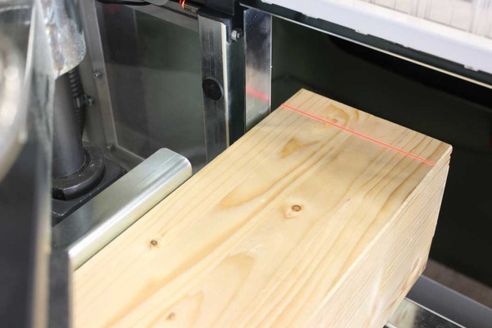

• Laser positioning.

• Special cutting tool.

The ZAF 250 executes the full range of tenons quickly, accurately, efficiently and precisely. For straight or angled tenons, corner or ridge half-lap joints, you can always count on the ZAF 250 Tenoner. To ensure exact length measurements, the stop is adjust on a scale.

Developed specifically for the ZAF 250, the cutting tool can be rapidly adapted for different tenon lengths and half-lap joints.

The ZAF 250 has precision setting options and clearly laid-out control panel. Precise positioning on the timber is facilitated by a new build-in laser. The result is cuts which are accurate to the nearest millimeter (inch) in all types of timber!

After setting the desired tenon geometry, the cutter head automatically executes the required shape - including angled, haunched and chamfered cuts. Chip waste is extractable as a matter of course.

For hardwood applications, we recommend the ZAF 250 with adjustable feed rate.

The 3m (9,8ft) long support profile with mm scale and length stop allow precise positioning of the workpieces.

Cleared, transparent layout- the controls of the ZAF 250 for automatic or manual operation.

New laser technology allows positioning of the workpiece after marking.

Straight and angled renons are executed in a single work cycle as the control permits machining on 4 sides. These also allows all-round chamfering of the tenons.

Simply tilt the cutting unit to execute angled tenons.